You Are Here:Home > Information dynamic

> Industry Trends

News Navigation

What should be noted when choosing odorless E0 grade environmentally friendly particleboard for maki

source:www.niaotech.com Time:2025-12-15

To make a wardrobe with odorless E0 grade environmentally friendly particleboard, it is necessary to control the authenticity and quality of the board itself, as well as the production process, selection of supporting accessories, and later acceptance and use protection. This ensures both environmental friendliness and durability of the wardrobe. Specific precautions are as follows:

1. Strictly verify the environmental protection and quality of the board

Confirm environmental certification and report: Do not trust the E0 level verbally promoted by merchants. It is necessary to actively request recent testing reports with CMA and CNAS authoritative certifications to verify whether the formaldehyde emission in the report meets the E0 level standard. At the same time, avoiding marketing gimmicks such as "zero formaldehyde", there is currently no zero formaldehyde particleboard wardrobe.

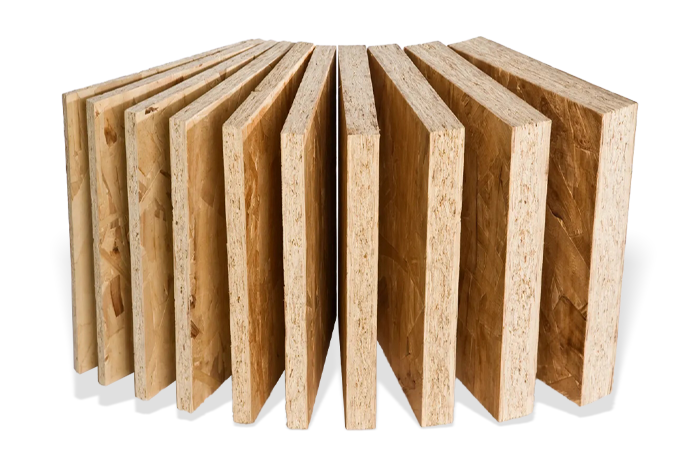

Check the quality of the board foundation: The particle distribution of excellent particleboard is uniform, with no obvious voids or large pieces of wood on the cross section, and the surface is flat and smooth without defects such as damage or bulges. In addition, high-density particle board with a density of ≥ 700kg/m 3 should be selected. This type of board has stronger load-bearing capacity for wardrobe cabinets, is not easily deformed, and is suitable for making load-bearing parts such as plywood.

2. Pay close attention to the details of the production process

Prioritize excellent edge sealing technology: Edge sealing is the key to blocking formaldehyde release and moisture resistance, and laser or PUR edge sealing is preferred. Laser edge sealing has no glue marks and good sealing performance; PUR edge sealing is resistant to high and low temperatures, not easy to peel off, and suitable for humid areas. To avoid EVA edge sealing, its adhesive has a large amount of water and is prone to aging and cracking.

Carefully inspect the quality of edge sealing: check whether the edge sealing strip is seamlessly connected to the edge of the board (gap ≤ 0.1mm), and touch it with your hand without burrs or bumps. Also pay attention to whether the color, texture, and board of the edge banding match, and ensure that there are no broken edges or missing corners after trimming. The edge banding will not fall off when pulled hard.

Pay attention to the environmental protection of auxiliary materials such as glue: Inquire with merchants about the types of glue used for board pressing and wardrobe assembly, and prioritize products that use formaldehyde free or low formaldehyde environmentally friendly glue such as MDI glue and soy glue. Resolutely avoid urea formaldehyde glue that contains a large amount of formaldehyde. Merchants can also be required to provide environmental testing reports for the glue.

3. Control supporting accessories and customization details

Screening for environmentally friendly and durable hardware: Poor quality hardware may release heavy metals or harmful gases, and reputable companies such as Heidi Shi and Bailong should be selected. For example, hinges should open and close smoothly, have strong load-bearing capacity, and slide rails should be pulled without jamming, which can not only avoid environmental hazards but also extend the service life of wardrobes.

Reasonable planning of wardrobe structure: Particle board has average moisture resistance. If the wardrobe is located near damp areas such as bathrooms or balconies, open grid design can be reduced during customization, or moisture-proof boards can be installed on the back and sides of the cabinet. The spacing between the layers should not be too large to avoid overloading and deformation. If necessary, reinforcement strips can be added.

4. Carry out acceptance and post use protection measures

Careful inspection upon receipt: After opening the wardrobe cabinet door, if there is a pungent odor, be alert and use a formaldehyde detector for a simple test. At the same time, check whether the wardrobe is deformed as a whole, whether the board connections are loose, and whether the hardware is installed firmly.

Pay attention to post installation ventilation and maintenance: After installing a new wardrobe, it is necessary to maintain indoor ventilation for a period of time to accelerate the emission of residual formaldehyde. In daily use, avoid prolonged exposure of the wardrobe to damp environments. When cleaning, wipe with a dry cloth or neutral cleaner to prevent the edges from getting damp and falling off.

1. Strictly verify the environmental protection and quality of the board

Confirm environmental certification and report: Do not trust the E0 level verbally promoted by merchants. It is necessary to actively request recent testing reports with CMA and CNAS authoritative certifications to verify whether the formaldehyde emission in the report meets the E0 level standard. At the same time, avoiding marketing gimmicks such as "zero formaldehyde", there is currently no zero formaldehyde particleboard wardrobe.

Check the quality of the board foundation: The particle distribution of excellent particleboard is uniform, with no obvious voids or large pieces of wood on the cross section, and the surface is flat and smooth without defects such as damage or bulges. In addition, high-density particle board with a density of ≥ 700kg/m 3 should be selected. This type of board has stronger load-bearing capacity for wardrobe cabinets, is not easily deformed, and is suitable for making load-bearing parts such as plywood.

2. Pay close attention to the details of the production process

Prioritize excellent edge sealing technology: Edge sealing is the key to blocking formaldehyde release and moisture resistance, and laser or PUR edge sealing is preferred. Laser edge sealing has no glue marks and good sealing performance; PUR edge sealing is resistant to high and low temperatures, not easy to peel off, and suitable for humid areas. To avoid EVA edge sealing, its adhesive has a large amount of water and is prone to aging and cracking.

Carefully inspect the quality of edge sealing: check whether the edge sealing strip is seamlessly connected to the edge of the board (gap ≤ 0.1mm), and touch it with your hand without burrs or bumps. Also pay attention to whether the color, texture, and board of the edge banding match, and ensure that there are no broken edges or missing corners after trimming. The edge banding will not fall off when pulled hard.

Pay attention to the environmental protection of auxiliary materials such as glue: Inquire with merchants about the types of glue used for board pressing and wardrobe assembly, and prioritize products that use formaldehyde free or low formaldehyde environmentally friendly glue such as MDI glue and soy glue. Resolutely avoid urea formaldehyde glue that contains a large amount of formaldehyde. Merchants can also be required to provide environmental testing reports for the glue.

3. Control supporting accessories and customization details

Screening for environmentally friendly and durable hardware: Poor quality hardware may release heavy metals or harmful gases, and reputable companies such as Heidi Shi and Bailong should be selected. For example, hinges should open and close smoothly, have strong load-bearing capacity, and slide rails should be pulled without jamming, which can not only avoid environmental hazards but also extend the service life of wardrobes.

Reasonable planning of wardrobe structure: Particle board has average moisture resistance. If the wardrobe is located near damp areas such as bathrooms or balconies, open grid design can be reduced during customization, or moisture-proof boards can be installed on the back and sides of the cabinet. The spacing between the layers should not be too large to avoid overloading and deformation. If necessary, reinforcement strips can be added.

4. Carry out acceptance and post use protection measures

Careful inspection upon receipt: After opening the wardrobe cabinet door, if there is a pungent odor, be alert and use a formaldehyde detector for a simple test. At the same time, check whether the wardrobe is deformed as a whole, whether the board connections are loose, and whether the hardware is installed firmly.

Pay attention to post installation ventilation and maintenance: After installing a new wardrobe, it is necessary to maintain indoor ventilation for a period of time to accelerate the emission of residual formaldehyde. In daily use, avoid prolonged exposure of the wardrobe to damp environments. When cleaning, wipe with a dry cloth or neutral cleaner to prevent the edges from getting damp and falling off.

Previous:

none

Next:

What are the applicable scenarios for odorless E0…

Related articles

+

wechat number:底部微信

Home

Home

Wechat

Wechat

Tell

Tell